No.1 Quality of Surface Grinding Machine Manufacturer - Ahmedabad

Prayosha Enterprise is a India’s one of the most trusted Surface Grinding Machine Manufacturers and exporters in Ahmedabad. The genuine grade raw materials used in manufacturing generate the machine highly stable and robust in structure. The surface is also appointed with a powder coating that provides an excellent finish and safety against rust-causing conditions.

This Surface grinding machine is primarily employed to machine the job piece so as to get smooth finishing on the exterior and is done by subjecting the job to the machine’s grinding wheel. This abrasion produced by the rotating grinding wheel ideally makes the flat surface smooth as per the requirement.We are the chief manufacturers of Surface grinding machine in India and we manufacture them utilizing excellent quality materials obtained from trustworthy vendors.

They are fabricated employing state-of-the-art technology accessible so far. We make these machines accurately and uphold their quality at all phases of fabrication. Henceforth they are enormously enduring. These types of machinery are lucrative and power efficient and provide exceptional productivity. We offer a wide range of this type of machine which includes CNC Surface Grinding Machine and Flat Surface Grinding machines in conjunction with their spares.

Prayosha Enterprise is a Most trusted Surface Grinding Machine manufacturer, Expertising in delivering best-quality and precision-engineered grinding solutions. As a head in the industry, we offer a broad range of advanced surface grinding machines that certify superior performance, durability, and accuracy for many industrial applications. Our machines are designed to meet the proper demands of industries such as automotive, aerospace, and heavy manufacturing. With a focus on delivering rare surface finishes, our grinding machines are made for efficiency, reliability, and precision. At Prayosha Enterprise, we are committed to providing creative surface grinding solutions that better productivity and verify consistent, high-quality results.

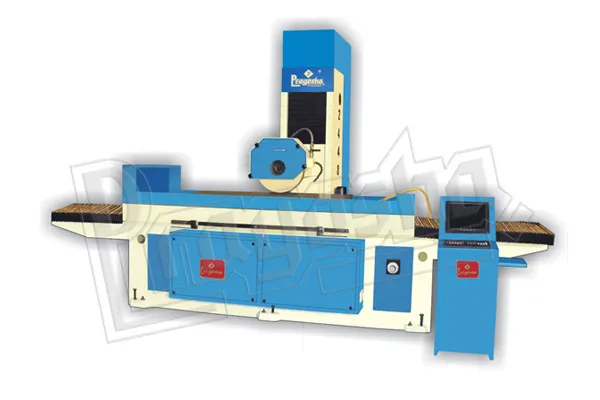

Grinding Machine - Surface Grinder Machine

A grinding machine is a machine that grinds or polishes a surface to remove any irregularities. The abrasive wheel that is used for polishing rotates at a high speed. When it comes to surface grinding, a surface grinding machine is a great instrument. The surface grinder is used to remove any up and down movement from a surface and smooth it out. The surface grinder machine is used in a variety of sectors due to its durability.

The grinding wheels on the surface grinding machine make it ideal for rough surfaces. The grinding machine goes forward and backward to execute its purpose of removing any element existing on the surface. The surface grinding procedure is followed by a polishing process using several additional equipments.

Grinding Machine for the Surface

We have a large selection of grinding machines, including manual surface grinders. Metals and other things are grounded with them. A grinding wheel that rotates at a high rpm is used in the manual surface grinder. The workpiece is manually fed to the wheel for grinding using a lever. This lever aids in workpiece location in relation to the abrasive wheel.

Surface Grinding Machine Hydraulic

The hydraulic surface grinder is one of the grinding machines offered by Prayosha Tools. Metals and other materials are primarily ground with these instruments. For flat and smooth surfaces, hydraulic surface grinder equipment is employed. It gets its power from a hydraulic source, which ensures that the equipment runs smoothly.

Grinding the Surface

It belongs to one of the distinctive grinder patterns designed specifically for industrial uses. It can still be used for a wide range of crushing applications. Surface grinding has outstanding safety measures that enable for a simple grinding operation for any user. It has automated grinding tool adjustment, which ensures that the side portion of the workpiece is also adequately ground.

M Series Surface Grinding Machine

Prayosha introduces the M series surface grinding machine, a flexible piece of machinery that is ideal for face grinding work materials. An M series surface grinding machine performs this procedure of carefully polishing the face of any workpiece and ensuring that the surface is free of any imperfections.

Cylindrical Grinding Machine Hydraulic

Prayosha Enterprise has a large selection of grinding machines, including cylindrical grinders. Metals and other materials can be ground with these tools. The hydraulic cylindrical grinding machine is designed for applications that need high precision and complex operations. It has been approved for use in mass production and tool rooms.

Grinder with fewer centers

Prayosha has a large selection of grinding machines, including centerless grinders. Metals and other materials are primarily ground with these instruments. A centerless grinder has two wheels, one stationary and the other moving, both rotating in the same direction but at different speeds. The quicker wheel removes the material from the workpiece in chips, resulting in a smooth surface.

Surface Grinding Machine Features

The purpose of a surface grinding machine is to give an object a smooth surface. The surface grinding machine is a powerful tool that aids in the smoothing of surfaces. These machines are extremely productive because they can grind at a faster rate than manual tools. The surface grinder is known for producing precise results during ground surfacing while also providing the operator with a pleasant experience. The manner of conducting duties varies based on the model of the surface grinding machine. The portability of the grinder also varies depending on its shape and size.

Surface Grinding Machine Benefits

A surface grinding machine has a number of advantages of below.

- Flexibility

- Precision

- Completing

- Surface grinders are versatile because they can be used to grind various surfaces of metallic and non-metallic materials. The abrasiveness and hardness of the substance may also differ. These grinding machines are noted for offering remarkable accuracy and finish to various surfaces. Whether the machines are automatic or manual, they provide different results. An automatic machine is simple to operate, however, manual machines can be adjusted rapidly and instantly to meet the needs.

Surface Grinder Machine Industrial Applications

Depending on the needs of the industry, each type of grinder is important in different industrial applications. A surface grinder is used to smooth out various pieces of machinery that must be in excellent form according to the appropriate measurements. Different metals benefit from the use of these surface grinding equipment. Plastics can also be processed with this equipment. These devices are employed in industries such as autos, where the precise size of ball bearings is required, and windmills, where the panes must be at a perfect angle. This sort of machine is used in a variety of sectors, including ceramics and piston ring producers.

Surface Grinding Machine

A surface grinding machine is an equipment that helps to produce a smooth finish on metallic or nonmetallic materials. Oftentimes, surfaces such as steel, aluminum, granite, and others require an even finish and include removing excess material. The terminated material is then sophisticated to realize the desired product.

Manufacturers can use surface grinding equipment to achieve dimension and excellent surface quality. Surface grinding machines can work with a variety of materials and provide a high level of precision. Surface grinders are available in both automated and semi-automatic variants to fulfill all of your finishing requirements.

Why has Grinding Machinery been used as a powerful tool throughout industries?

The strong grinding machine tools produce goods with a high surface polish and precise dimensions. It’s a type of production machine tool used in the manufacturing business to achieve the desired finish, size, and shape of a work piece. The cylindrical and flat surfaces of various materials are finished with the grinding machine. The machines can work for longer periods of time without taking breaks, resulting in increased productivity. Advanced grinding machines aid in the mass production of identical products. Identical manufacturing is an important component of a company’s operation, and a grinding machine can produce high-quality work with a small margin of error and a smooth finish on a variety of surfaces where other machining equipment might not be.