Best Quality of Surface Grinding Machine Manufacturer

Our Aim is Take Your Surfaces to the Next Level – With Our Advanced Grinding Technology. As per the set industry standard norms, the provided products are produced using cutting-edge latest technology and quality tested raw material at our infrastructural unit.

“Prayosha Enterprise” is the leading used surface grinding machine, Surface Grinding Machine in India. We hold expertise in Surface Grinding Manufacturer and are an exporter in South Africa, Brazil, Kenya, Algeria, Ecuador, Angola, Uganda, Bahrain, Oman, Indonesia, Qatar, UAE, and the global market. Our Surface Grinding finds application in different industries. Our active team is encircled to design the qualitative surface grinding machine which is far better than the other company’s machines. Our well-organized machinery provides flawless performance and is durable in nature. Not only is the offered product best in utilization but also cost-effective for the consumers.

Our well equipped surface grinding machine manufacturer are producing by utilizing the standard quality raw materials to maintain its sturdiness. A huge list of consumers from many different countries is extensively availing our products due to its unique features and fine finish. Customers from Asian, African and European countries broadly like our machineries because we are conducted give them on affordable price ranges.

Famous Brand for Surface Grinding Machine Supplier in Ahmedabad

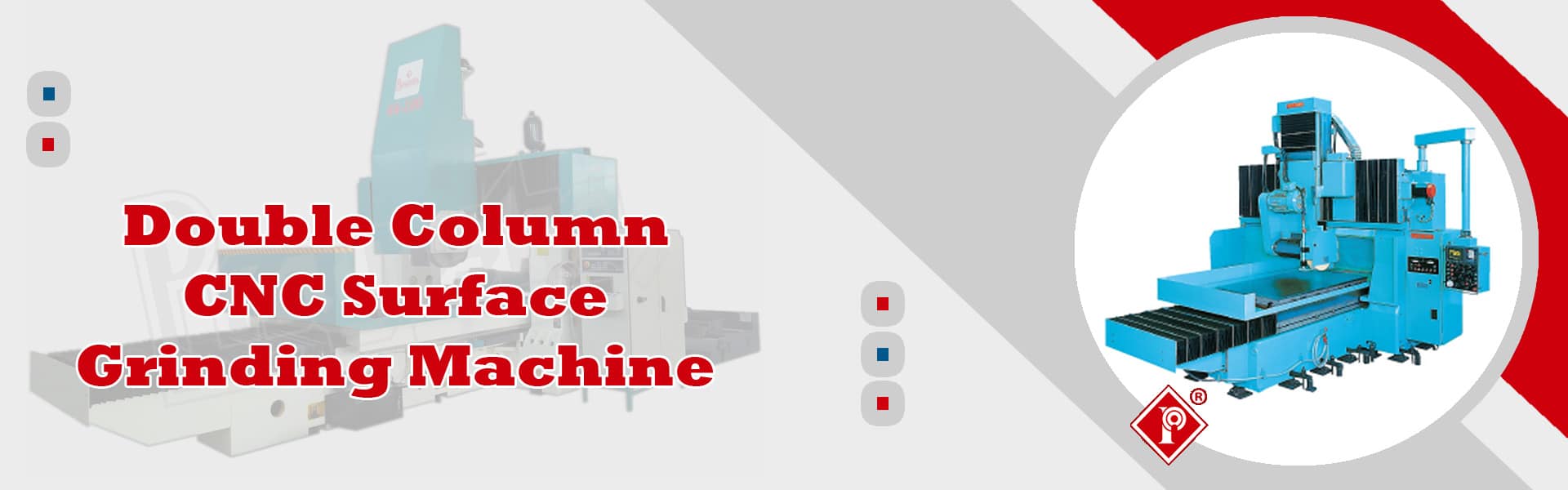

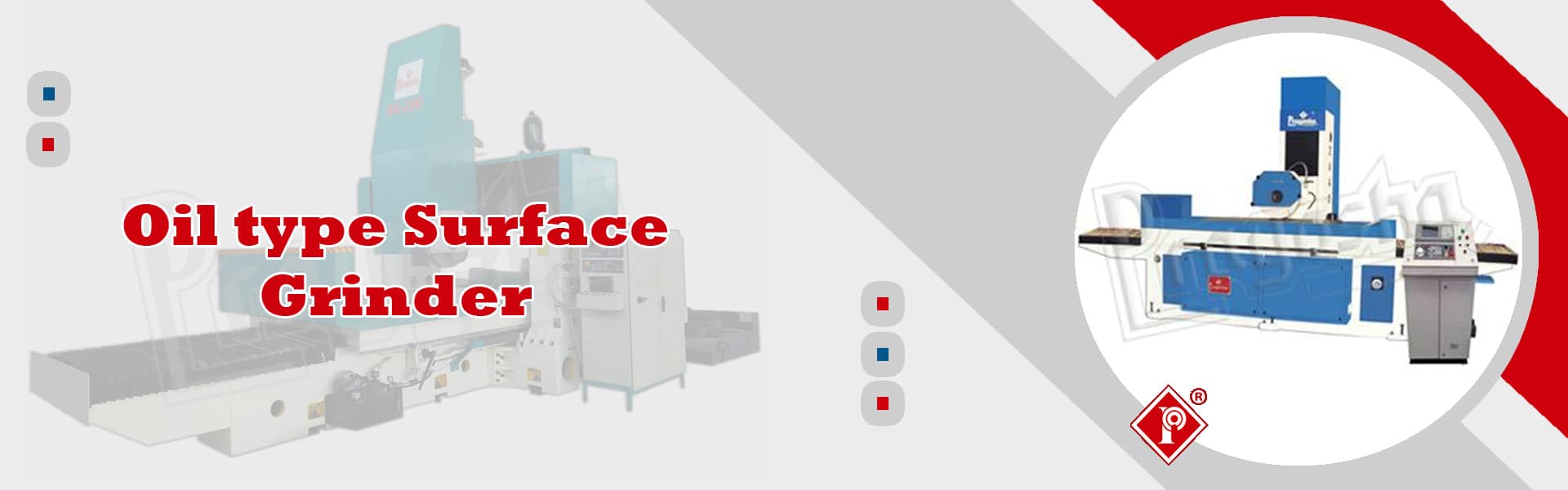

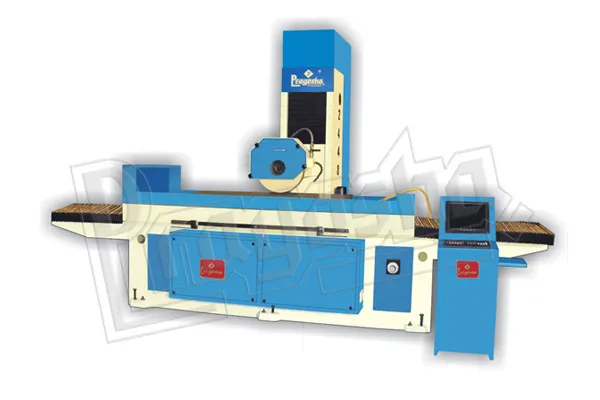

We introduce ourselves as a top-ranked Surface Grinding Machine manufacturer in India; we are offering Surface Grinder Machine cutting-edge era and innovation under the brand name Prayosha. Prayosha Surface Grinders has developed different sizes of Surface Grinder machine like Manual Surface Grinders, Precision Surface Grinding machines, manual surface grinders, precision Surface grinding machines, vertical surface grinders, horizontal surface grinding, CNC surface grinding Machine, and hydraulic surface grinding in oil and ball types with overall first-class control and cutting-edge. Our surface grinder machines are really vibration-loss machines for noiseless operations. Accuracy on the machine is guaranteed, as is the smoothness of the machine operator.

Surface grinding machines offer various grinding tools, such as manual surface grinders or polishing machines that remove surface irregularities. The polishing process is applied using a high-speed rotating abrasive wheel. A surface grinding machine is An effective instrument for surface grinding. The surface grinder is used to smooth out surfaces and remove any ups and downs that may be present. The Surface grinding machine has found usage in numerous sectors due to its durability. There are numerous industries that employ surface grinding equipment. The surface grinder adjusts surfaces by removing all kinds of ups and downs. There are numerous industries that employ surface grinding equipment.

What is Surface Grinding Machine?

The surface grinding machine is applicable to formulate the downy finish on the plane surface. This machine is the most common tools for grinding operations. It is a finishing process that uses a rotating grinding wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more pure look by removing the oxide layer and degradation on workpiece surfaces. This will also reach the want surface for a functional purpose. A machine vise placed on the magnetic chuck can be used to hold non-ferromagnetic workpieces if only a magnetic chuck is available. Some types of surface grinders are also capable of producing contour surfaces with formed grinding wheels.

The grinding machines consist of a divan by means of a match to steer and grasp the workpiece, and power has driven the grinding wheel spinning at the obligatory rapidity. The rapidity is determined by the wheel’s width and the manufacturer’s evaluation. The grinding head can travel diagonally over a rigid workpiece, or it can be stimulated while the grinding head remains in a fixed position.

Surface Grinding Machine Manufacturers In India

- Industries We Serve

We are Surface Grinding Machine Supplier for various types of Industries.

Advantages Of Surface Grinding Machine

- It is possible to grind solid or rough materials

- Provide High degree of dimensional correctness

- Makes surface textures of most elevated terminate

- Tooling process gets cheaper

- Automatically functioned machine, so provides the fast result

- Use proper wheel protectors on all grinding machines

- No adequate amount of speculation is requisite

- Working functions of this machine is simple to understand

- supplementary skills are not compulsory

- far better as compared to the other processing machines

- Large reduction ratio, best design of chamber and big crushing efficiency

Applications

- Mining

- Building materials

- Chemical Industries

- Metallurgy

- Highway materials

- Railway

- Water conservancy

Used Surface Grinding Machine Price

- Outer surface of cylindrical substances can be grinded

- This machine is capable of preparing the transmission bushing, shouldered pins and stoneware shafts for simulator force

- This equipment is proficient for finishing the pointed, direct and created holes specifically

- Used for sharpen the milling cutters, taps, other various machine cutting tool cutter and reapers

- Also utilized for grinding the hard materials

Why Us?

- We are supplying the complete quality tested machines

- Affordable price ranges are determined

- Our machine is much capable to grind heavy materials

- Prompt actions are taken regarding the requirements of consumers

- Improving the technological development in the product, as per the changing technology

- Embattled to provide the 100% customer satisfaction

- Best company in market, for providing the well demanded machineries to the reliable consumers with the advanced features

Working Procedure Of Surface Grinding Machine

- At the very first stage, aluminum, stainless steel, brass and plastics materials clog the grinding wheel while being processed

- When grinding process runs at high temperatures, the material tends to become weakened and it starts to get crushed and also more inclined to corrode. This can also result in a loss of magnetism in materials where this is applicable

- The grinding wheel is not limited to a cylindrical shape and can have a numberless option that is functional in transferring varied figures to the entity for work on

- Straight wheels can be completely attired by the machinist to construct convention figures

- When surface grinding an objective, the mechanist must keep in mind that the shape of the wheel will be transferred to the material of the entity like a overthrow figure